Feedback on 3DR® Formwork: Patrick LABUSSIERE, Spie Batignolles

Patrick LABUSSIERE, SCGPM, Spie Batignolles, answers our questions about the TDF construction site carried out with Dipy formwork.

The DIPY formwork was invented by the same people who developed the current 3DR. As a user of both versions, we would like to hear your impressions on these two technologies.

1. You used the DIPY formwork on the TDF construction site. Can you tell us why you chose it?

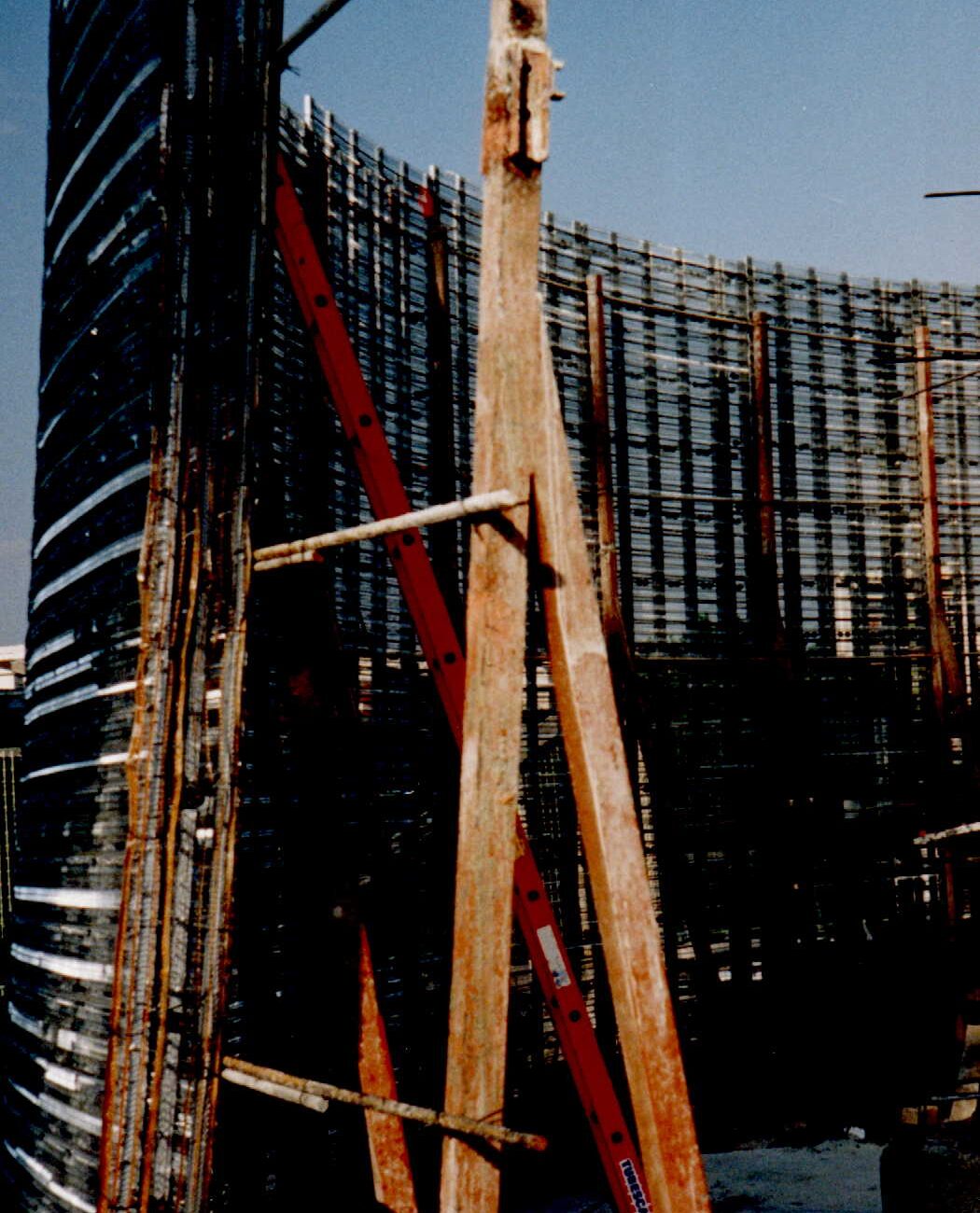

Firstly, the particular shape of the structure. The DIPY formwork, which adapts to specific shapes, was the solution to this particular problem.

Secondly, as the technical adage goes, “the project manager is based on three criteria: the first is ‘how much does it cost?’, the second is ‘how much does it cost?’, and the third is ‘how much does it cost?'” Starting from this principle, and comparing the different alternatives that were available to us, it was decided that DIPY was the most cost-effective system.

In addition, the DIPY system allows for the elimination of one step, that of form removal, in the logistics chain, thus saving time, which is an obvious advantage on a construction site.

2. What were the other alternatives for this project?

The cone shape of the structure gave us the choice between different techniques:

– Climbing formwork

– Shotcrete

– The DIPY filtering formwork system

Each of these methods was considered for this project and the Dipy formwork, even though the technique was recent, had major advantages in terms of cost and time.

3. Since then, you have tested the 3DR version. Do you think this new generation better meets the needs of the construction site…

…in terms of time? The 3DR filtering formwork eliminates two phases on the construction site, reinforcement and formwork removal, resulting in a significant time savings.

…in terms of durability? Thanks to the Dipy filtering system, the concrete eliminated some excess water and resulted in a less porous concrete. The 3DR continues this principle and combines a woven, three-dimensional reinforcement cage. The durability seems further strengthened with the new 3DR technology.

…for other reasons? With the 3DR technology, the reinforcements are installed in the factory. The construction site thus gains in safety, time, and simplification of organization.

4. What improvements do you expect from this technology…

…in terms of the construction site? If there were improvements to be made to the system, I think it would be in terms of safety equipment and accessories on the vertical walls.

Moreover, a new method requires a learning phase. But despite this apprehension, the time and difficulty of training are singularly short.

…for the project owner? You know, project owners react more like financiers than technicians. So it is essential to emphasize the durability induced by the system.

…for the project manager? It’s the same thing, you have to make sure to reassure the client and guarantee that, with tests and trials, 3DR walls, even of great height, can withstand the pour.

5. According to your company, what are the relevant applications of this process?

Obviously, the 3DR process is far superior to other systems in terms of specific shapes, rehabilitation, and walls cast against the ground or against an existing structure.

In addition, due to the lightweight of the walls, it seems ideal in case of a crane ban (near schools or certain underground sites).

I think that in the long run, it will become a serious competitor to traditional formwork for all “classic” construction sites.

6. Are you ready to use 3DR on upcoming projects?

Yes, after a technical-economic assessment. It is certain that the 3DR system is ideal for the structures mentioned before and that it has a secure future in construction sites.